Air Flow Sensor

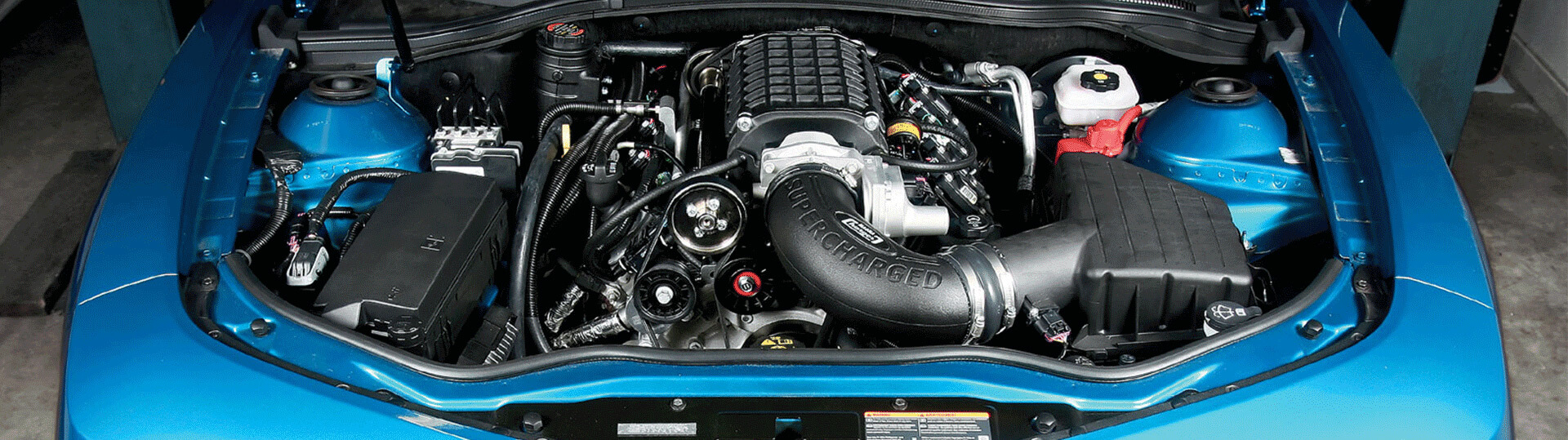

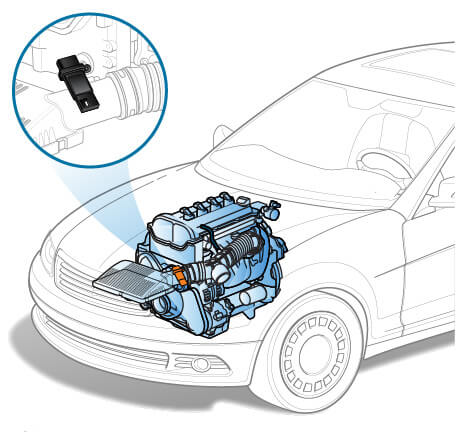

What is a mass air flow sensor and how does it work? Understanging answers on these essential questions will give you some good ideas about engine’s performance increase. A Mass Air flow Sensor (MAF sensor) is a car electronic fuel injection system component. It is installed between the air filter and the intake manifold of the engine.The air mass information is necessary for the engine control unit (ECU) to balance and deliver the correct fuel mass to the engine.

What does air flow sensor do?

Now, when you know what air flow sensor is, there is one more question left: what does a MAF sensor do. A mass air flow sensor is used to find out the mass of air entering a fuel-injected internal combustion engine. The air mass information is necessary for the engine control unit (ECU) to balance and deliver the correct fuel mass to the engine. Air changes its density as it expands and contracts with temperature and pressure. In automotive applications, air density varies with the ambient temperature, altitude and use of a turbocharger and this is an ideal application for a mass sensor. (See stoichiometry and ideal gas law.)

The performance mass air flow sensor provides the open-loop predicted air flow information (the measured air flow) to the ECU, and the oxygen sensor provides closed-loop feedback in order to make minor corrections to the predicted air mass.

Types of Air Flow Sensors

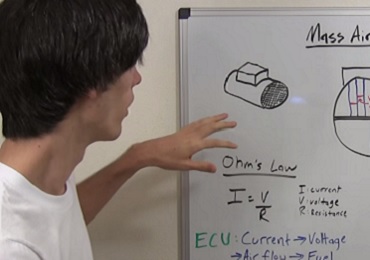

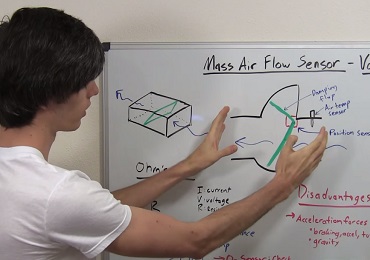

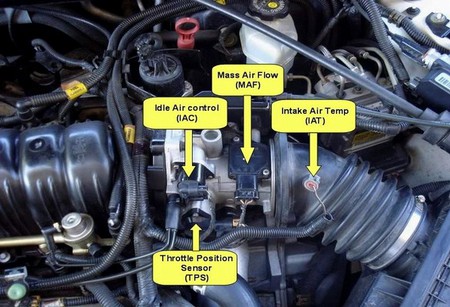

There are two common types of mass airflow sensors in usage on automotive engines. These are the vane meter and the hot wire. Neither design employs technology that measures air mass directly. However, with an additional sensor or two, the engine's air mass flow rate can be accurately determined.

Both are used almost exclusively on electronic fuel injection (EFI) engines. Both sensor designs output a 0.0- 5.0 volt or a pulse-width modulation (PWM) signal that is proportional to the air mass flow rate, and both sensors have an intake air temperature (IAT) sensor incorporated into their housings. When a car MAF is used in conjunction with an oxygen sensor, the engine's air/fuel ratio can be controlled very accurately.

On electronic fuel injection (EFI) cars, the airflow sensor (air flow meter) could be an air flow restriction, depending on which type of air-flow sensor is used. The hot-wire airflow sensor, which is often called the performance mass air flow sensor, doesn't present much restriction to the air flow as it is usually about the same size as the bore of the air intake duct. If you need to increase the bore of a MAF sensor, you can swap out the mass airflow sensor for a larger one from the same car manufacturer, but you would need to reprogram the engine contrl unit (ECU) so that it can accurately measure the increased air flow rate. If your stock ECU is not reprogrammable, you may need to install a programmable aftermarket ECU. These air flow meters usually have a fine wire mesh at either end of the bore. Removing this wire mesh will lead to a 1% to 2% increase in power at maximum RPM.