A manual transmission contains cogs for selecting gears. These cogs have matching teeth, called dog teeth, which means that the rotation speeds of the two parts have a synchronizer, a device that uses frictional contact to bring the two parts to the same speed, and a locking mechanism called a blocker ring to prevent engagement of the teeth (full movement of the shift lever into gear) until the speeds are synchronized. If you drive a manual transmission car, you may be surprised to find out that it has more than one performance clutch. And it turns out that folks with automatic transmission cars have clutches, too. In fact, there are clutches in many things you probably see or use every day: Many cordless drills have a clutch, chain saws have a centrifugal clutch and even some yo-yos have a clutch.

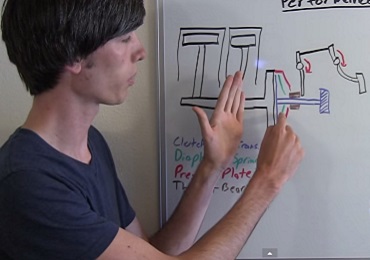

To understand how a car clutch works, it helps to know a little bit about friction, which is a measure of how hard it is to slide one object over another. Friction is caused by the peaks and valleys that are part of every surface -- even very smooth surfaces still have microscopic peaks and valleys. The larger these peaks and valleys are, the harder it is to slide the object. A clutch works because of friction between a clutch plate and a flywheel.

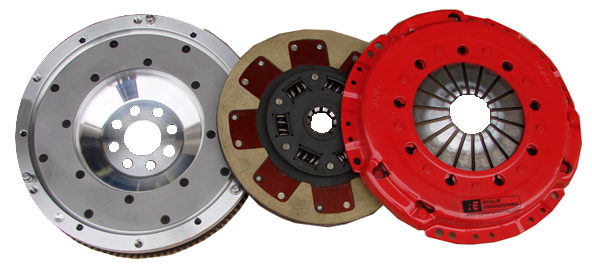

When your foot is off the pedal, the springs push the pressure plate against the car clutch disc, which in turn presses against the flywheel. This locks the engine to the transmission input shaft, causing them to spin at the same speed. The amount of force the car clutch can hold depends on the friction between the clutch plate and the flywheel, and how much force the spring puts on the pressure plate.

How does a clutch impact on performance

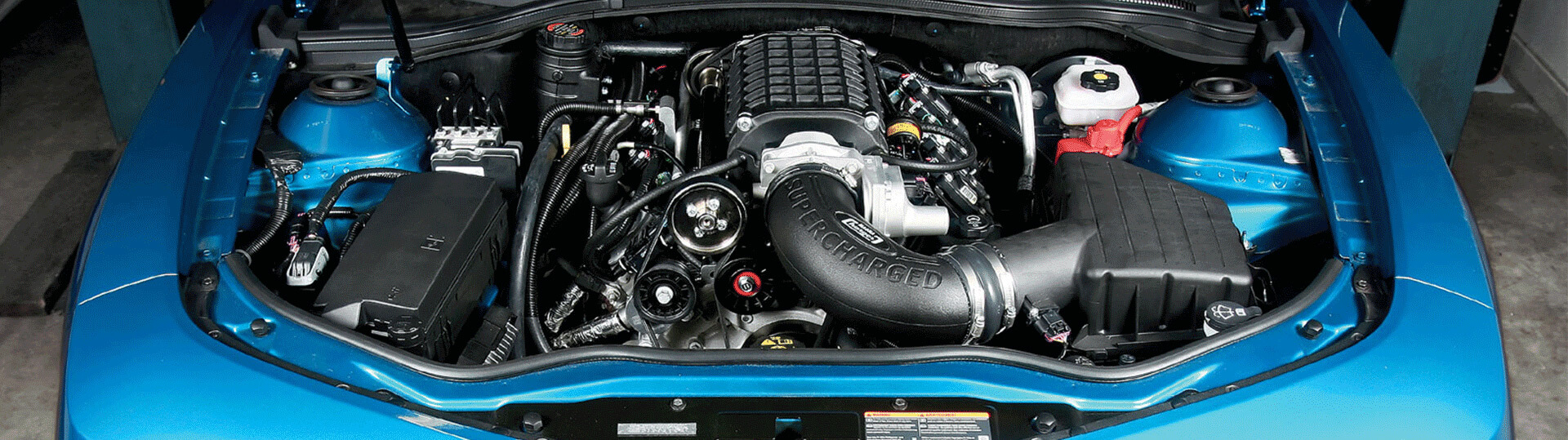

FLYWHEELS: The actual horsepower of the engine does not change related to the weight of the flywheel. However, to increase the engine RPM, and accelerate the car, all rotating weight (as well as the entire car) must be speeded up. This requires power, and the heavier the part, the more power needed to speed it up.

The trade-offs are as follows: the heavier the flywheel, the smoother the idle, the easier the starting is from a stop, and the smoother the cruising/slight throttle changes are. BUT - the slower the acceleration is. The lighter the flywheel is, the harder it is to get the car moving from a stop (just requires a somewhat higher RPM before the car clutch is let out - which wears the clutch faster), depending on porting, intake, and exhaust, the idle will be somewhat rougher, and some "jerkiness" may be noticed while cruising. BUT - you will be able to accelerate faster. This is true to a much lesser degree on fuel injected engines than on carbureted engines.

The above reasons are why there are basically three types of flywheels offered. The stock units are fine for most "normal" driving, as done by the vast majority of drivers. The light steel ones are great for "spirited" street driving, middle range autocross classes, some drag racing (heavier is sometimes better), and just general high-performance applications that will still be driven on the street sometimes. The lighter aluminum flywheels are recommended for all road race applications and fuel injected street driven cars where the highest performance is desired.

CLUTCH DISCS: These are what most affect the "feel" of the clutch engagement. The range and "feel" of pedal travel between disengaged, and fully engaged, is determined by the cushioning spring between the sides of the fiber disc (or lack of), and by the sprung center piece (or lack of) between the outer engagement material, and the spline center going to the transmission. The cushioning spring between the engagement sides increases the range of pedal travel between "starting" to engage, and fully engaged. This is due to the pressure plate having to compress the spring to fully clamp on the disc. The discs without this spring are a very much more "abrupt" grab, which makes them harder to drive smoothly on the street.

Discs with the fiber lining wear at normal rates, under normal driving conditions, but disintegrate if overheated, and/or driven REAL hard and abused.

The metal fiber "puck" type discs, for the most part, wear the flywheel and pressure plate faster than the disc. They will take much more heat and punishment before failure, but do not like to be "slipped" very much (burns up the flywheel/pressure plate first).

A normal car clutch in an automatic transmission vehicle lasts around 50,000 miles. Performance clutches in manual transmission vehicles tend to last longer and may last for 100,000 miles. The actual life of the performance clutch however depends on usage. Careful handling extends the clutchs life to between 80,000 miles and 120,000 miles, whereas rough usage could end the clutch's life at around 35,000 miles. Frequent use of the clutch owing to rash driving, when driving through bad roads and through areas of high traffic tend to wear away the clutch faster.